Projects

Select category for project gallery- Accumulator Systems

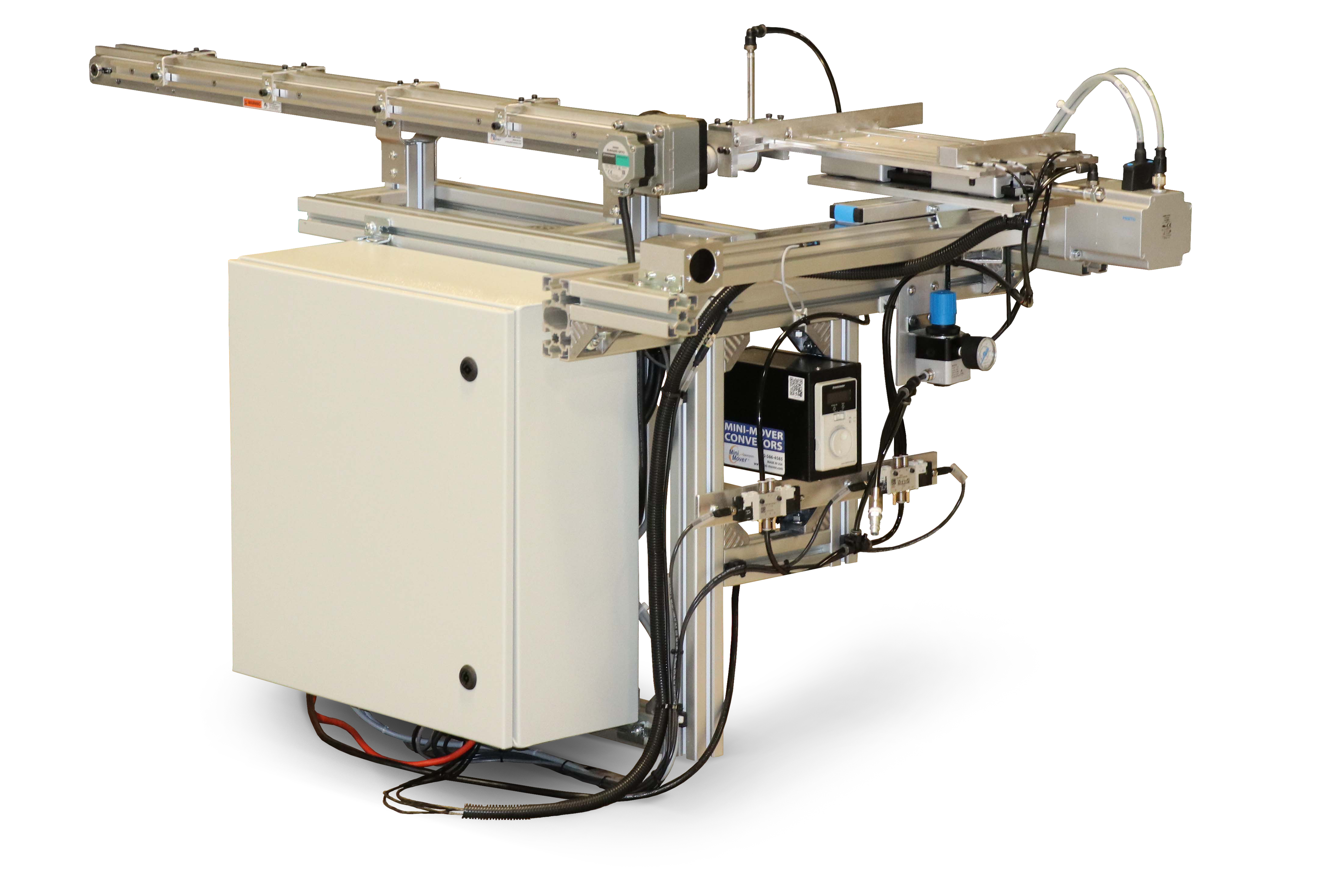

- Automation

- Control Consoles

- Custom Cylinders

- Custom Solutions

- Enclosures

- Extruded Aluminum Systems

- Filter Carts – Offline Loop

- Hydraulic Manifolds

- Lube Systems

- Machine Rebuilding

- Mobile Controls

- Outriggers

- Panel Shop

- Pneumatic Assemblies

- Power Units

- Repair

- Robotic Cells

- Service

- Smart Cylinders

- Test Stands

Contact Us (800) 333.7004

From the actuators up, our engineers can design and build a complete system for your production equipment or special purpose test machines. Whether you supply the tooling and fixturing, or if we design to your specifications, our automation experience will help minimize your cost and get your new system up and running quickly.

Our experience with most of the common types of prime movers will help you choose the best hydraulic, pneumatic or electrical drives to fit your system needs.

Projects

Select category for project gallery- Accumulator Systems

- Automation

- Control Consoles

- Custom Cylinders

- Custom Solutions

- Enclosures

- Extruded Aluminum Systems

- Filter Carts – Offline Loop

- Hydraulic Manifolds

- Lube Systems

- Machine Rebuilding

- Mobile Controls

- Outriggers

- Panel Shop

- Pneumatic Assemblies

- Power Units

- Repair

- Robotic Cells

- Service

- Smart Cylinders

- Test Stands

Contact Us (800) 333.7004

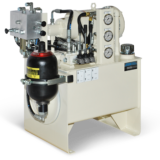

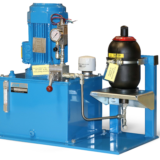

Accumulator racks tie individual accumulators with individual shutoffs to a common header, gas connection, and optional automatic bleed down function. Accumulator racks can be made of bladder or piston type accumulators. Typical accumulator volumes range from 5 to 30 gallons per accumulator and racks can range in size from one to 12 accumulators per rack. However, multiple racks can be combined to form larger systems.

Additional options include :

- Gauges

- Pressure transducers with or without displays

- Stackable connections to combine multiple accumulator racks

- Piston position transducers

- Thermal exhaust relief